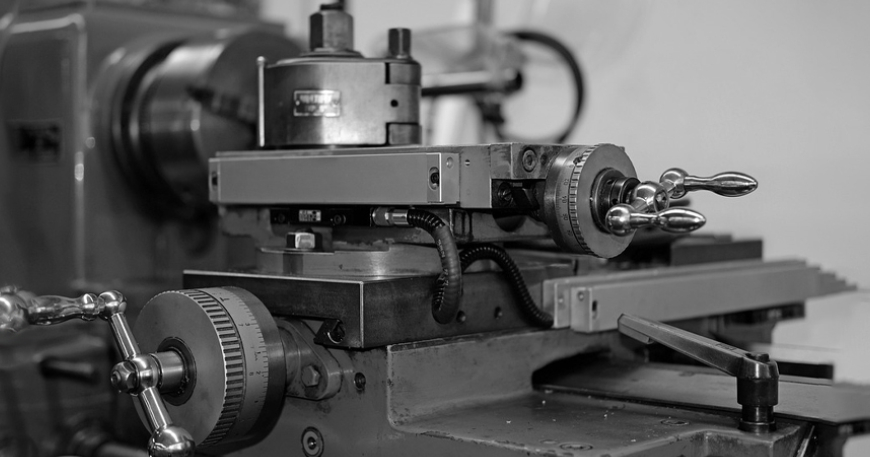

Do you want to explore the accessories for the lathe machines & their uses? If yes, then here you can collect the necessary details about lathe accessories. In general, accessories of the lathe machines are the most essential component to improve the functionality and versatility of the machine. These carefully designed add-ons are effectively designed to increase the lathe capabilities and enabling it to execute the different range of tasks with efficiency and precision. Accessories let machinists to grab complex and intricate machining operations from cutting, shaping, threading or drilling. It can ensure the highest level of precision & accuracy.

Impact of lathe machine:

Generally, lathe machine is the great precision machine that secures the workpiece using the chuck and place the cutting tool on the toolpost. It can effectively operate by perfectly rotating the workpiece along the central axis. It can facilitate the different range of lathe operations. The overall operation of the lathe machine consists of different tasks like facing, turning, thread cutting, chamfering, drilling, knurling and much more. Using more cutting tools, a lathe machine from india can craft objects carefully.

What are the lathe machine accessories?

Check out below for the lathe machine accessories

- Centres

- Tipped centre

- Ordinary centre

- Insert type centre

- Ball centre

- Pipe centre

- Half centre

- Frictionless centre

- Chucks

- Three jaw universal chuck

- Four jaw independent chuck

- Collet chuck

- Magnetic chuck

- Combination chuck

- Carriers or catch plates

- Face plate

- Angle plate

- Mandrels

- Rests

- Follower rest

- Steady rest

Attachments of lathe machine:

There are also different attachments have been used in the lather machine. Such attachments are:

- Taper turning attachment for lathe

- Milling attachment for lathe

- Gear cutting attachment for lathe

- Grinding attachment for lathe

- Spherical turning attachment for lathe

Conclusion:

From the above mentioned scenario, now you have got the idea about accessories for lathe machines and their uses. So without further delay, you can make use of it for your project.