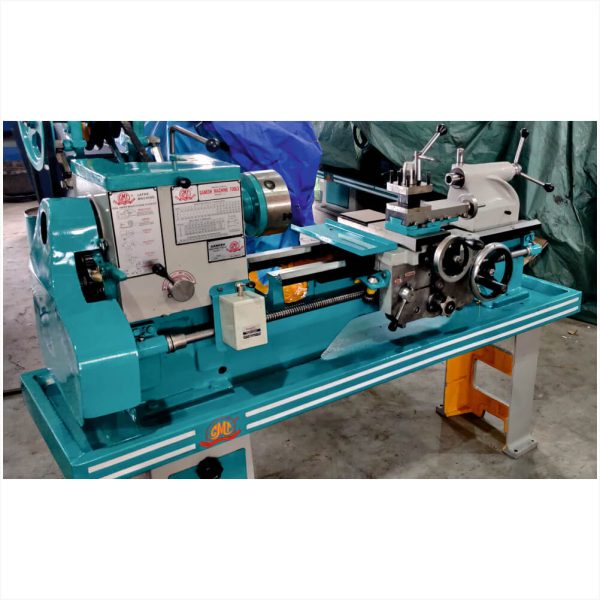

Description

Technical Specifications

Accessories

Applications

Videos

FAQs

| BED | |

|---|---|

| Bed Type | 2V and 2 Flat |

| Bed Length | 1370 mm/4.1/2Feet |

| Bed Width | 235 mm |

| Gap Length | 120 mm |

| CAPACITES | |

| Height of Centre | 165 mm |

| Swing Over Bed | 320 mm |

| Swing Over Gap | 510 mm |

| Swing Over Cross Slide | 180 mm |

| Admit Between Centre | 660 mm |

| Movement of Cross Slide | 215 mm |

| Movement of Compound Slide | 110 mm |

| HEAD STOCK | |

| Taper Bore in Spindle Sleeve | MT-3 |

| Spindle Thread | 6 TPI |

| Spindle Bore | 41 mm |

| No. of Spindle Speed | 8 |

| STANDARD ACCESSORIES | EXTRA ACCESSORIES |

|---|---|

| Change Gear Set (Inch & mm) | Steady Rest |

| Chuck Plate | Follow Rest |

| Centre Adaptor | Face Plate |

| Dead Centre (2 No.) | Norton Gear Box |

| Main Drive ‘V’ Belt | Taper Turning Attachment |

| Motor Pully | Electric Motor |

| Rear Tool Post | |

| Coolant Pump | |

| Belt & R.F. Switch |

- GMT Light Duty Cone Pulley Lathe machines are ideal for industries with light and semi operations,

- Industries Where high Precision and Fast Production is Required,

- GMT Light Duty Cone Pulley Lathe is widely used in Colleges,

- we are Renowned for our Expertise in Tool Room OF Mechanical Engineering Colleges,

- We Have supplied In MIT’s & Various Private ITI’s .

- Apart from That this are widely used For Small & Medium Industries For all Kind of Turning Needs.

A:- A Light Duty Cone Pulley Lathe Machine is a versatile lathe designed for small to medium-sized workpieces. It is ideal for precision turning, facing, threading, drilling, boring and taper turning in workshops, tool rooms, and educational institutes.

A:- They are widely used in workshops, training centers, small manufacturing units, and repair shops where precision and compact design are required for machining lighter components.

A:- The machine uses a stepped cone pulley system to transfer motion from the motor to the spindle. By changing the belt position on the pulley steps, the operator can achieve different spindle speeds suitable for various operations.

A:- These machines are best suited for softer to medium-strength materials such as mild steel, aluminum, brass, plastic, and wood. They can also handle small jobs in stainless steel and cast iron within their capacity limits.

A:- The turning capacity depends on the specific model, including swing over bed, center height, and distance between centers. Light duty models typically handle smaller jobs compared to medium or heavy-duty machines.

A:- Standard accessories often include a 3-jaw chuck, tool post, centers, faceplate, motor pulley, and belt. Optional accessories may include a 4-jaw chuck, taper turning attachment and steady rest.

Technical Specifications

Accessories

Applications

Videos

FAQ

Download Catalogue

| MODEL | GMT-AGM 1 | GMT-AGM 2 |

|---|---|---|

| Length of Bed | 4’6″ (1370mm) | 6′ (1825mm) |

| Width of Bed | 279mm | 279mm |

| Length of Gap | 115mm | 115mm |

| Length of Gap in Front of Face Plate | 130mm | 130mm |

| Admit Between Center | 18″ (457mm) | 36″(915mm) |

| Floor Space (mm) | 1550 x 900 | 2000 x 900 |

| Approx Case Dimension (mm) (L x W x H) | 1650 x 1000 x 1330 | 2100 x 1000 x 1330 |

| CAPACITY | |

|---|---|

| Height of Center | 226mm |

| Swing over Bed | 432mm |

| Swing over Cross Slide | 280mm |

| Swing in Gap | 660mm |

| Movement of Cross Slide | 275mm |

| Movement of Coumpound Slide | 145mm |

| THREADS | |

|---|---|

| No. of Inch Thread (British) | 44 |

| Range of Inch Thread (British) | 2 TPI to 60 TPI |

| No. of Metric Thread | 24 |

| Range of Metric Thread | 0.5mm to 15mm Pitch |

| Lead Screw Dia/Pitch | 1.25″(31.75mm) 4 TPI |

| Range of Longitudinal Feeds | 0.066 to 2mm/Rev. of Spindle |

| Range of Transverse Feeds | 0.0165 to 0.50mm/Rev. of Spindle |

| MAIN SPINDLE | |

|---|---|

| Type of Spindle | A2-5/A2-6/Threaded |

| Spindle Bore | 52mm |

| Spindle Morse Taper | MT-6 |

| Spindle Adapter Morse Taper | MT-4 |

| No. of Spindle Speed | 8 |

| Spindle Speed Range | 40 to 1200 RPM |

| TAIL STOCK SPINDLE | |

|---|---|

| Diameter | 50.8mm |

| Morse Tapper | MT-4 |

| Travel | 140mm |

| ELECTRIC MOTOR |

|---|

| 2 HP/1.1 KW |

| STANDARD ACCESSORIES | EXTRA ACCESSORIES |

|---|---|

| Induction Hardened bed ways | Face plate |

| Chuck plate 1 nos | Carrier plate |

| Center adapter | Steady rest |

| Dead centers 2 nos | Follow rest |

| Tool Post Spanner | True Chuck, Dog Chuck |

| Motor Pulley | Rear splash guard |

| Thread dial indicator | Quick change tool post |

| Chabge gear set (For metric and inch both) | Motorized apron |

| Norton Gear Box Single Screw/Double Shaft | Power brake |

| Taper turning attachment | |

| Motorized coolant pump with tank and fittings | |

| Rear Toolpost | |

| Electrical (Motor, Switch, Wiring, V-belts and fittings) |

Why Medium Duty All geared is Best Tool Room Machine?

Our All Geared Medium Duty Lathe Machines are extensively used in various fields like automobiles/ Rubber Roller / Sugar mill / Paper mill / heavy engineering and over & above all general engineering maintenance workshops.

Having various Speed Options and Proper torque you can Use this machine efficiently From normal turning to Medium Heavy applications.

this machine is more balanced Compared to light Duty All geared and Due to more enter height you use it easily for making Dies.

A:- We Generally Suggest Light Duty All Geared Lathe Machine To our Industrial Buyers As This machine is specially Designed For ALL YOUR TOOLROOM Application Works.

A:- This is suitable for industry such as submersible motor workshops, Repairing workshops, textile industry , small components industry, for automobile industry, for small manufacturing units till 1 meter job length size or below.

A:- We regularly Export to Other countries and in Many countries you can get Ready Reference Of buyers as well.

A:- We Generally suggest all the Standard accessories Like Chuck, Motor, Coolant and Machine Lamp but there are many other accessories that can be bought which are listed as follows.

Face Plate , Carrier plate, Steady Rest, Follow Rest, Rear Splash Guard, Power Brake ,

Electric Panel, Rear tool Post etc.

Face Plate , Carrier plate, Steady Rest, Follow Rest, Rear Splash Guard, Power Brake ,

Electric Panel, Rear tool Post etc.

A:- yes, A complete one year piece to piece spares support ( if not met with machine accident) is covered in machine purchase

For out of India clients courier charges would be extra at actual.

For out of India clients courier charges would be extra at actual.

A:- We generally provide Manual and oil charts and daily indication points for machine maintenance