Slotting machines are an integral part of the manufacturing and metalworking industries. Known for their precision and versatility, these machines are designed to create slots, grooves, and other intricate shapes in materials like metal and wood. In this blog, we will delve into the essential aspects of slotting machines, their applications, maintenance, and the importance of choosing the right slotting machine suppliers.

What is a Slotting Machine?

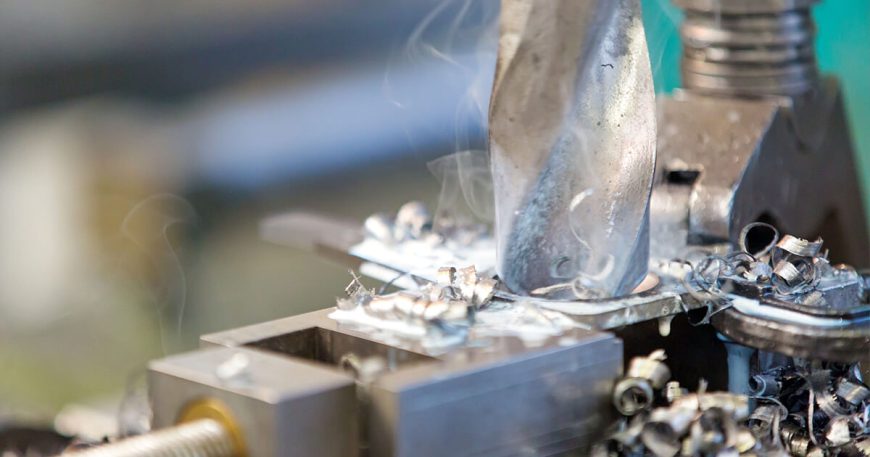

A slotting machine, also known as a slotter, is a tool designed to cut precise slots and grooves into a workpiece. It operates using a reciprocating motion where a cutting tool moves vertically to remove material. Slotting machines are ideal for jobs that require intricate shaping, making them a staple in industries like automotive, aerospace, and tool manufacturing.

Applications of Slotting Machines

Slotting machines have a wide range of applications, including:

- Gear Manufacturing: Creating keyways and splines in gears.

- Tool Production: Shaping tools, dies, and molds with high accuracy.

- Automotive Components: Cutting grooves in engine parts and other automotive components.

- Metalworking: Producing intricate patterns and slots in various metal parts.

Types of Slotting Machines

- Puncher Slotting Machines: Ideal for heavy-duty industrial use, these machines are designed for large-scale production.

- Precision Slotters: Used for fine, detailed work requiring high accuracy.

- CNC Slotting Machines: Equipped with advanced automation for enhanced precision and efficiency.

Importance of Industrial Slotting Machines

Industrial slotting machines are crucial for large-scale production, offering unparalleled precision and efficiency. Their ability to handle a variety of materials and tasks makes them indispensable in modern manufacturing.

Key Features to Look for in Slotting Machines

When selecting a slotting machine, consider:

- Build Quality: Opt for machines made from durable materials to ensure longevity.

- Ease of Operation: User-friendly controls are essential for maximizing productivity.

- Maintenance Requirements: Machines with straightforward maintenance needs reduce downtime and operating costs.

- Supplier Reputation: Trusted slotting machine suppliers provide reliable machines and excellent after-sales service.

Maintenance of Slotting Machines

Proper maintenance is vital to ensure the longevity and performance of your slotting machine. Here are some tips:

- Regular Lubrication: Keep all moving parts well-lubricated to prevent wear and tear.

- Routine Cleaning: Remove debris and residue after each use.

- Periodic Inspections: Check for any signs of wear or damage in critical components.

- Replace Worn Parts: Timely replacement of worn-out parts minimizes the risk of breakdowns.

Choosing the Right Slotting Machine Suppliers

Selecting a reliable supplier is crucial for acquiring high-quality slotting machines. Look for suppliers who:

- Offer a wide range of machines to suit diverse industrial needs.

- Provide robust customer support and maintenance services.

- Have a strong reputation for quality and reliability.

Conclusion

Slotting machines play a pivotal role in modern manufacturing, enabling precision and efficiency in various industries. Understanding their applications, types, and maintenance requirements is essential for optimizing their performance. Moreover, collaborating with trusted slotting machine suppliers ensures access to reliable equipment and support.

For further insights into slotting machines and their applications, explore this reference link.