Description

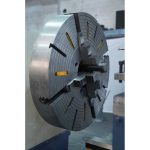

Technical Specifications

Accessories

Applications

Videos

FAQs

When considering an extra heavy-duty all geared lathe machine, make sure to assess your specific machining requirements, the types of materials you'll be working with, and the available features of the machine to ensure it meets your needs effectively.

For Selection of Machine , you need to select the type of bed , you can go for Leg type Lathe Machine or Plano bed type Lathe Machine.

then according to Center Height, you need to go for a little longer width of bed machine.

These machines are usually selected on the job Diagrams and functionality .

accessories column include

| STANDARD ACCESSORIES | EXTRA ACCESSORIES |

|---|---|

| Induction Hardened bed ways | Face plate |

| Chuck plate 1 nos | Carrier plate |

| Center adapter | Steady rest |

| Dead centers 2 nos | Follow rest |

| Tool Post Spanner | True Chuck, Dog Chuck |

| Motor Pulley | Rear splash guard |

| Thread dial indicator | Quick change tool post |

| Chabge gear set (For metric and inch both) | Motorized apron |

| Norton Gear Box Single Screw/Double Shaft | Power brake |

| Taper turning attachment | |

| Motorized coolant pump with tank and fittings | |

| Rear Toolpost | |

| Electrical (Motor, Switch, Wiring, V-belts and fittings) |

- Oil country where High Tongue is required

- Steel & paper mills Where there are various R.P.M requirements For Roll Turning and Precision Die Works

- Power plants – Heavy duty All Geared can be perfect Tool Room Machinery

- Ship building – For Extremely heavy Jobs Where Cone pulley Creates belt slippage All geared Provide High Torques

- Rubber Roller grinding – With Help of Various attachments You can Do Grinding applications on this machine.

A:- An Extra Heavy Duty All Geared Lathe Machine is a robust, high-performance lathe designed for machining very large and heavy workpieces. It uses an all-geared headstock instead of a cone pulley, which ensures powerful and precise speed control for industrial-grade applications.

A:- These machines are widely used in steel plants, shipbuilding, oil & gas, power plants, aerospace, railway workshops, defense, and large-scale heavy engineering industries, where large and heavy components are machined.

A:- The machine is capable of heavy turning, facing, threading, boring, drilling, taper turning, knurling, grooving, parting, and other precision machining tasks on extra-large workpieces.

A:- It can handle all ferrous and non-ferrous metals such as mild steel, stainless steel, alloy steel, cast iron, copper and aluminum, as well as very large and hard materials used in industrial applications.

A:- Turning capacity varies by model, but these machines generally feature large swing over bed, greater distance between centers (often several meters), and high bed length capacity for machining extra-large components.

A:- Depending on the size and model, the machine typically requires 7.5 HP to 20+ HP motors, with high torque for heavy-duty operations.