Description

Technical Specifications

Accessories

Applications

Videos

- All machines are customised and Designed as per customer needs.

- Please Contact us For Specifications with you Job Details.

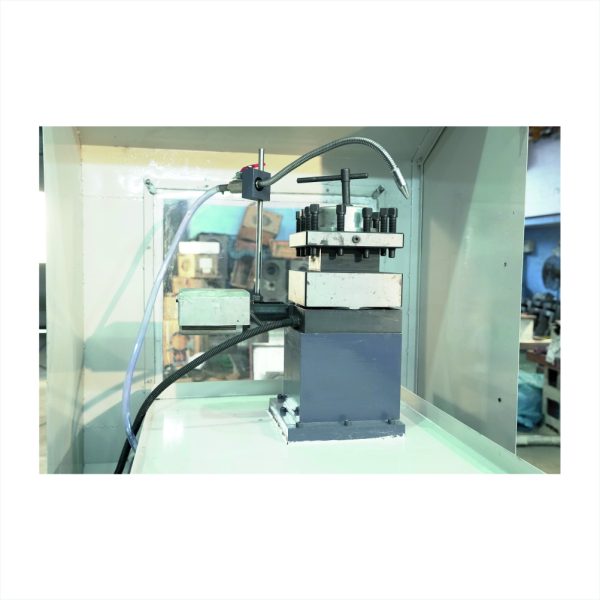

| STANDARD ACCESSORIES | OPTIONAL ACCESSORIES |

|---|---|

| 3 Jaw Manual Chuck OR 4 Jaw Manual Chuck | 4 Jaw Manual Chuck |

| 4 – Station Turret | Complete Fabrication System |

| Manual Tail Stock | Hydraulic Steady Rest |

| Bellow Cover | Hydraulic Follow Rest |

| Coolant System | 4-Position Coolant Thru Tool Post |

| Work Light | Horizontal 6-Position Tool Post |

| Automatic Lubrication System | Horizontal 8-Position Tool Post |

| Tool Box | Hydraulic Unit for chuck |

| Revolving center | Hydraulic Tail Stock |

| Air Condition | |

| Anti Vibration Pads |

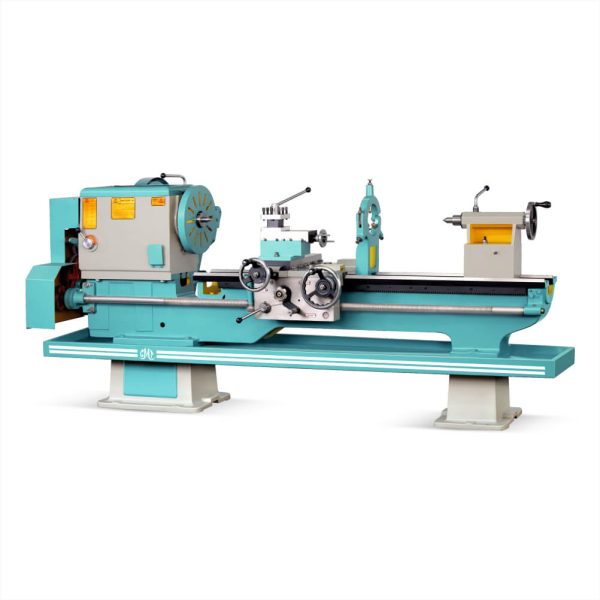

- Flat bed CNC feature supports for high speed turning and related machining operations

- For Roll Turning Customers like Rubber roller , cement industry, paper Industry, Plastic Industry

- Stays better, faster, reliable, and easy to operate than conventional lathes

- Suitable for applying complicated machining tasks including milling as well as drilling

- Flat Bed CNC lathe is perfectly used where jobs completion takes a long amount of time and where job turning is monotonous

- Ideal for screw barrel machines

- Worm making

- Automatic Grooving and various Roll Turning operations